Logistics Companies Process - An Overview

Table of Contents9 Easy Facts About Logistics Companies ShownMore About Logistics ServicesWhat Does Transport And Logistics Companies Mean?The 8-Minute Rule for Shipping

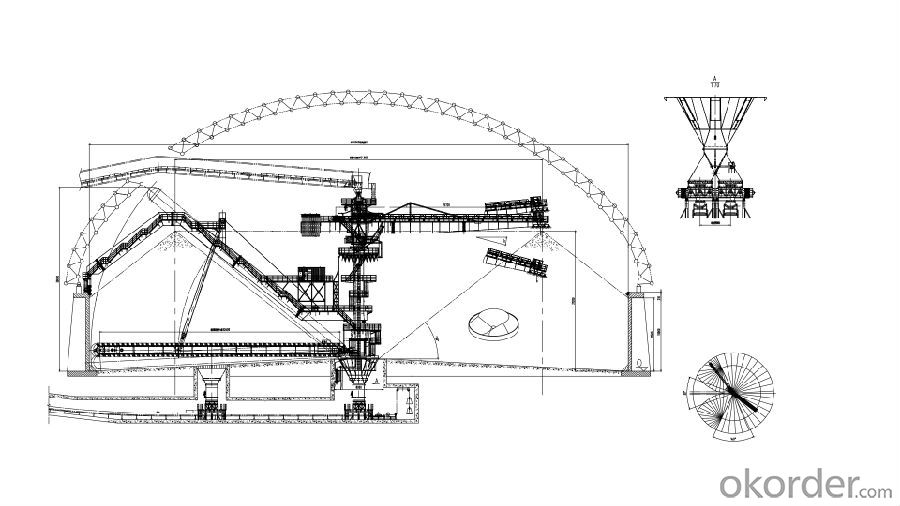

Wherever mass product is handled, Sandvik Mining's Product Location Mining Systems will be present. In enhancement to meeting the needs of the mining industry, the company likewise stands out in fulfilling the demands of downstream operations, such as power plants as well as mills, ports and also terminals with a technique customized for each and every application.As buffering, composing and homogenizing done by a stockyard can vary quantity along with high quality changes can be stabilized out with the appropriately selected system. freight logistics companies. As the concerns for every application and stockyard procedures are various, it is essential to take into consideration numerous inquiries before picking kind as well as size: throughput called for, qualities of the materials to be taken care of, co-opting result needed, open or roofed storage space and significantly, the future updating of the storage.

For accident avoidance systems it may be essential to designate the sensors against various other moving targets whereas for stockpile profiling they scan a strong ground as well as map its specific shape by producing 3D photos, which are stored in an inventory data source. "The essential demands of the systems is the toughness of the sensors, rapid signal action as well as dependable measuring leads to order to increase the machine accessibility and also to maintain high productivity levels of the makers under all functional conditions," says Branco Lalik, Product Supervisor for Products Handling, Sandvik Mining Equipments.

Logistics Companies Process - The Facts

From April to November, Wissota Sand & Crushed rock accumulations product 24-hours a day. "We pack out trucks 52-weeks a year, however we can just create material when Mother Nature lets us," says Dennis Simniok, a 30-year market professional who is supervisor of the business's Milwaukee, Wisconsin, United States pit.

Today, the website flaunts a 580ft (177m), pillar-supported, tripper conveyor, among the longest and highest in the area. The custom-made system was made by Superior Industries of Morris, Minnesota, U.S.A.. There are a lot of elements that led the procedure to replacing loader usage with a logistics companies copyright tripper conveyor system, one of the most crucial being safety and security.

Not only does it take some time as well as work to build and also berm a ramp for stockpiling, it results in significant material loss. logistics companies. Simniok emphasizes that also if it were risk-free for a loader to continuously run up and down a ramp, it takes a remarkable quantity of product to build the ramp and after that you wind up with a polluted stack.

Pretty quickly, the ramp is all unclean and also you have much less profitable item. When you fill trucks in the wintertime, you can only fill back to the ramp and afterwards you have actually obtained to pull back from it because the ramp is dirty and also you can't pack out that material. Every springtime, you have this filthy ramp to deal with product which you can just sell to sewage system service providers at a cut price," he claims.

Not known Incorrect Statements About Stockyard Equipments

We would normally put a couple of additional loaders on stockpiling for a several hours at the end of the day, so that one loader could maintain up with the work at evening. What's more, you need to take into consideration that each loader is stockpiling one pail each time.

We actually needed to take a close check out the expense visit this page of running these equipments," claims Simniok. Simniok claims that they chose to put in a tripper my link conveyor as a result of site constraints which asked for a long, slim, yet high-volume stockpile to meet demand. Conventional radial stackers would certainly not be able to get the job done.

"What we finished up with is a tripper conveyor system that runs neglected as well as accumulations at 450 brief lots (408 statistics tonnes) per hr with no guy hrs, no device, and also no fuel. Clearly, today's fuel costs are three-way what they were when we started up the system three years back.

3 Simple Techniques For Logistics Companies

Trippers are devices that discharge material from a belt conveyor at points upstream from the head sheave. A tripper consists of a framework supporting two idling wheels, one over and also onward of the other.

The conveyor belt itself drives a typical movable tripper, by an electrical motor, or by a cable and also winch. The tripper moves in an onward and also reverse direction to make a lengthy heap on one, or on each side of the belt conveyor. "Superior Industries came up with a tripper conveyor layout that truly fits our demands," says Simniok that notes the complying with specifications: v continual operation; a remote-controlled tripper cars and truck; remote-controlled discharge from one side to the other; capacity to be mounted on 57-foot-tall (17m) concrete columns; 30-inch (76cm) belt; ability to span at the very least 60-feet (18m) in between pillars; with the ability of constructing a big-volume stockpile of at the very least 180,000 brief bunches (163,293 metric tonnes); capability to handle 450 brief bunches per hour (408 statistics tonnes) of damp material without the head wheel spinning out Simniok claims that they selected the Superior Industries design over the competitive quotes as a result of the honesty of its structure.